빛으로 만드는 세상, 세상의 빛 미르호 주식회사

Thank you for visiting the homepage of Mirho Co., Ltd.

- SERIES

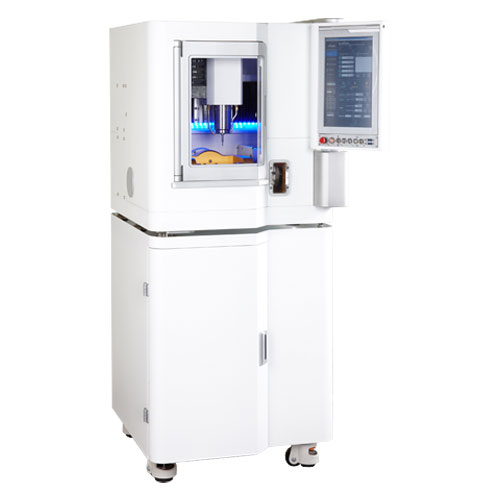

The LEOC industrial standard CNC machine tool is a space-efficient, precision-machined, compact MCT.

A wide range of general-purpose machines with stable machining accuracy and easy UI operation that can be easily used by non-experts.

Get started with MCT safely and easily.

| Specification | LEO 300 |

|---|---|

| Control Axis | 3-Axis |

| No. of Tools | 4 |

| Dimension (W × D × H) | 600 x 780 x 1800 |

| Movements(X,Y,Z,B) | 279 x 122 x 155 |

| Smallest Unit of movement(mm/degree) | 0.001 mm / 0.001 degree |

| Repeatability(μm) | 5(μm) |

| Weight | 336kg |

| Voltage / frequency | 220V / 50, 60Hz |

| Compressed Air | 6∼7 Bar |

| CAM | Open Solution |

| Motor drives | All servo motors with IP67 (Absolute type) |

| Reducer | Harmonic Drive |

| Milling Station | Wet |

| PC | Built-In |

| Monitor | 1280x800 IPS Touch Screen 10.1" |

| Spindle | Max Power output 3.6 kw, 30,000 RPM |

| Tools | 6mm shank tool with stop ring |

| Tool Change | Automatic Tool Change(Automatic tool length measurement) |

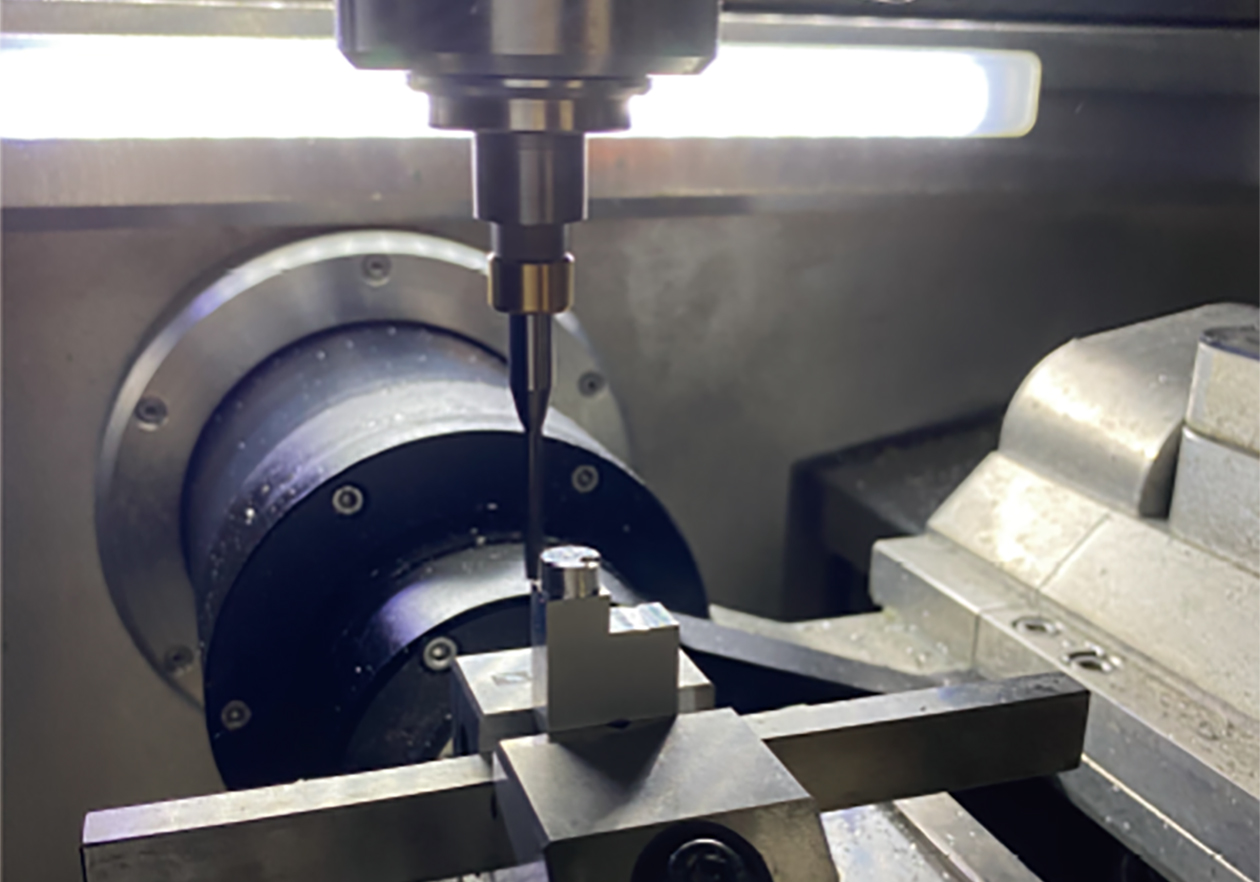

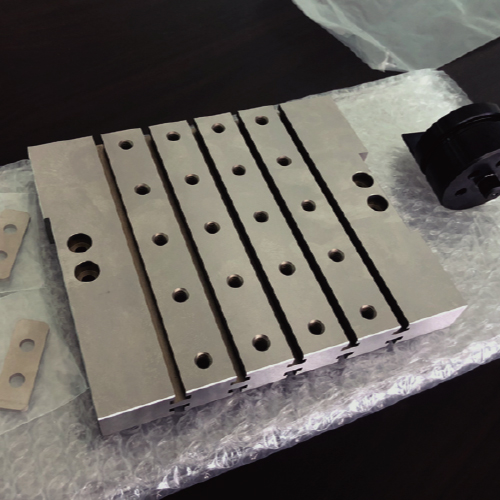

It is used in industrial precision parts and can be precise expression of up to 5 µm

Titanium SUS, which is very hard, or a soft wood aluminum, can be processed without restrictions on materials.

Various processing is possible with the implementation of a dedicated jig that fits the material on the bed -type master jig.

It also supports the optimal processing solution for the processing of the customer.

Circulature Coolant System makes it easy to manage processing chips and coolants.

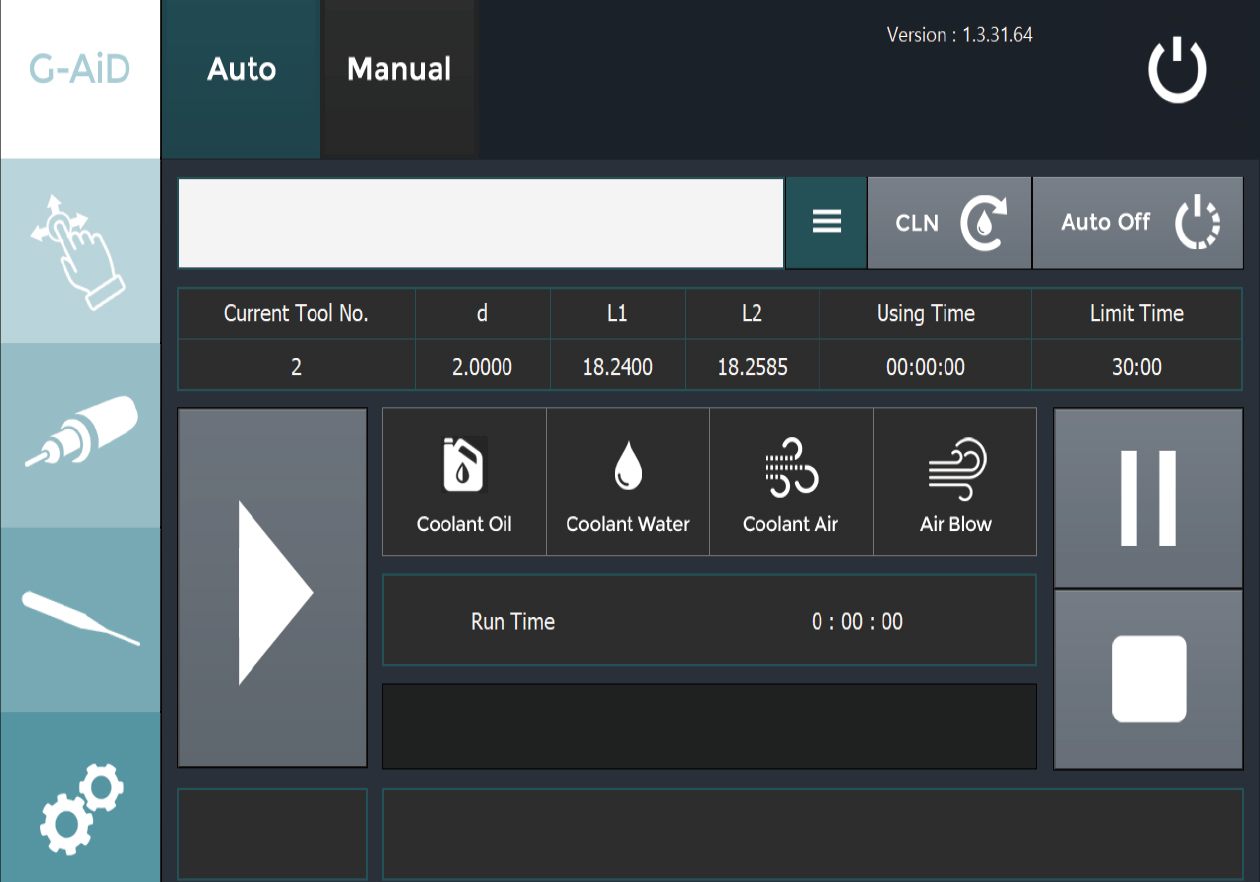

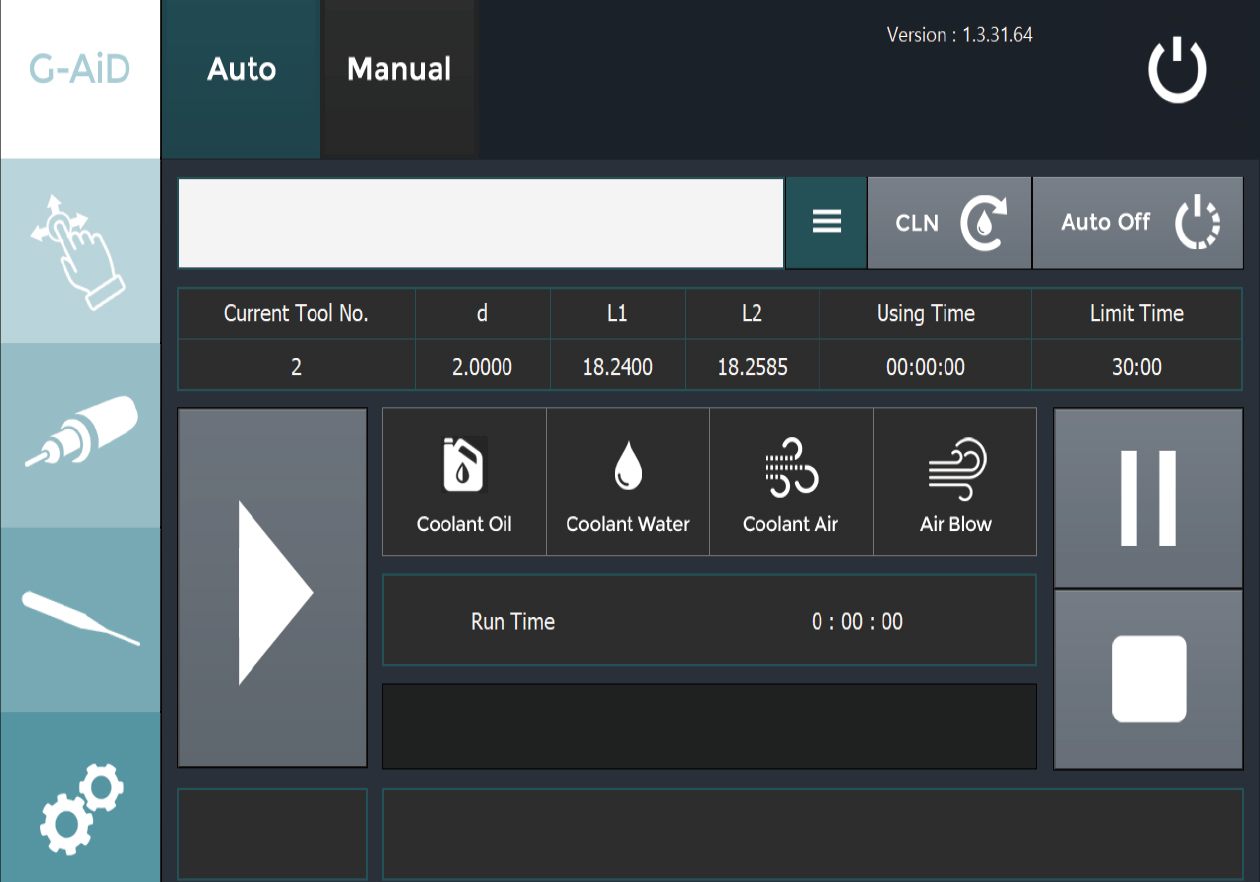

The SW developed by the user and the intuitive UI based on the touchpad, so that non -experts and students can easily operate.

The space utilization is enhanced by the size that can be placed six units compared to one general MCT, and can be used at the same time in the lab or classroom.

It can be safely used as an automatic locking system to restrict the axis of axis and to prevent overload spindle.

When the processing is completed, the equipment is automatically off, so there is no need to keep the machine in front of the machine all night.

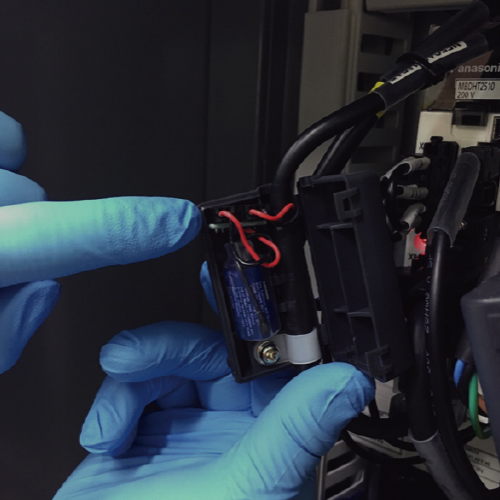

You can automatically measure the tool length with the attachment of the tool sensor in ATC to check the tool wear and the timing of replacing the tool accordingly.

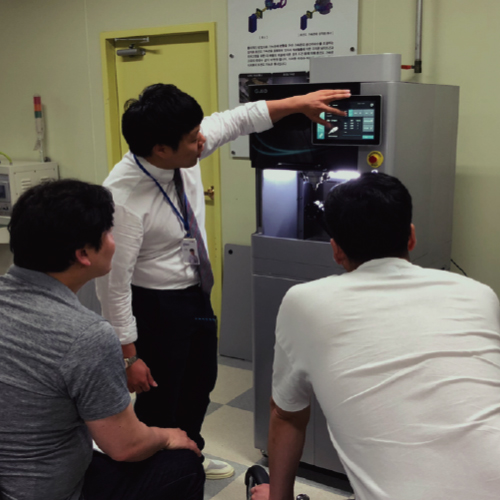

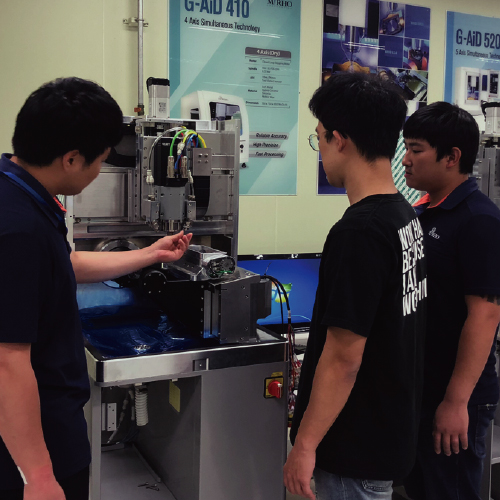

1. Provide basic equipment management training

2. Precision setting and maintenance training provided

It supports the zig technology coordination in line with the customer's processing language plan, and supports the best processing solution to make the customer process more efficiently.

In case of alarm and problems, remote support and visit A/S are supported to solve the problem quickly, and the main parts of the equipment are always managed by the head office to reduce the time required for the A/S.