Thank you for visiting the homepage of Mirho Co., Ltd.

- SERIES

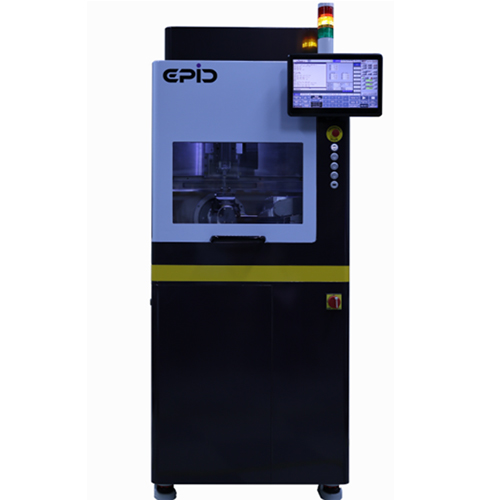

EPiC is a premium CNC machining machine for industrial use, equipped with a high-speed rotating spindle with twice the rotational speed of the original G-Aid, and realizing high-speed machining, the EPiC is the leader in small CNC, providing more powerful machining efficiency.

Added computational precision, faster communication, pre-reading control, and auto-calibration.

We support the optimal machining solution for your demanding parts.

| Specification | EPIC 500X |

|---|---|

| Control Axis | Simultaneous 5-Axis (5 axes simultaneously) |

| No. of Tools | 13 |

| Dimension (W × D × H) | 750 × 800 × 2100 |

| Movements(X,Y,Z,B,C) | 450 × 170 × 240, -45°+130°, ±360° |

| Smallest Unit of movement(mm/degree) | 0.001 mm / 0.001 degree |

| Repeatability(μm) | 5(μm) |

| Weight | 456kg |

| Voltage / frequency | 220V / 50, 60Hz |

| Compressed Air | 6∼7 Bar |

| CAM | Open Solution(FUSION360) |

| Motor drives | All servo motors with IP 67 (Incremental type) |

| Reducer | Harmonic Drive |

| Milling Station | Wet & mist(Coolant, Ethanol) & Air dry |

| PC | Built-In |

| Monitor | 1280 × 1024 IPS Touch Screen (14"~15”) |

| Spindle | Max Power output 2.6 kw, 60,000 RPM (Jaeger of Germany) |

| Tools | 6mm shank tool with stop ring |

| Tool Change | Automatic Tool Change(Automatic tool length measurement) |

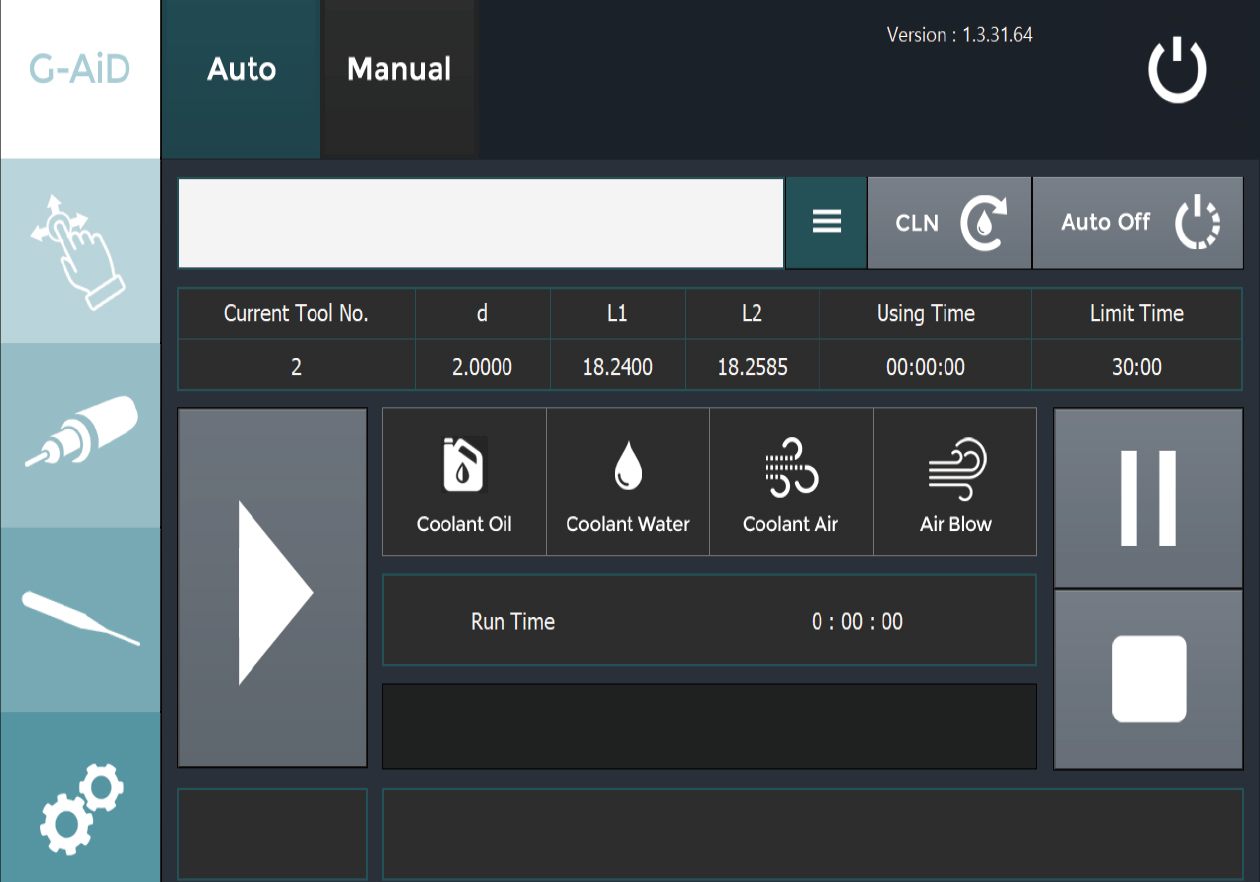

| Door | Auto Door Open/Close |

| Etc. | Tool tip point control Auto Calibration Signal tower Lamp(3rd led) |

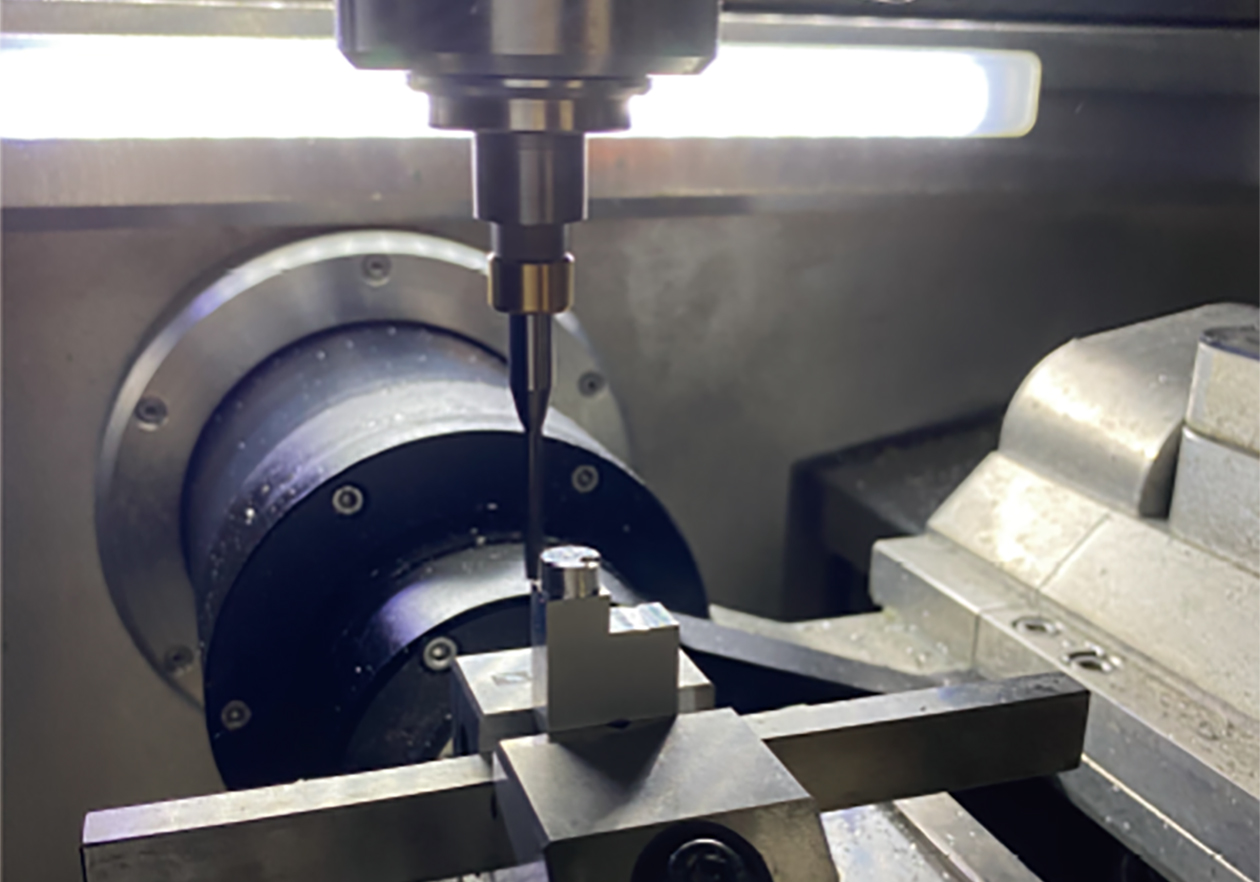

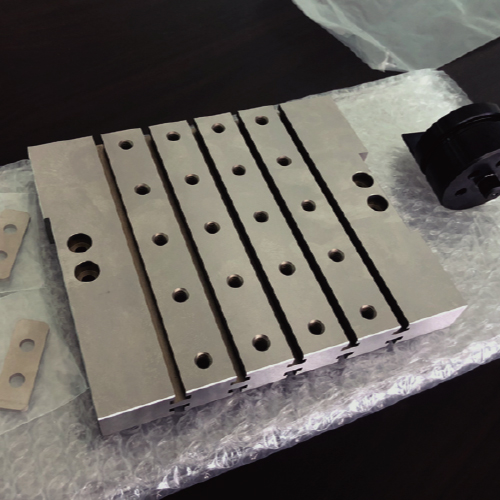

It is used in industrial precision parts and can be precise expression of up to 5 µm

Depending on the workpiece, the equipment spindle can be used selectively.

As a result of its test, the processing speed of up to 60000 rpm for industrial standards can be processed about three times faster than ordinary MCT.

Titanium SUS, which is very hard, or a soft wood aluminum, can be processed without restrictions on materials.

Various processing is possible with the implementation of a dedicated jig that fits the material on the bed -type master jig.

It also supports the optimal processing solution for the processing of the customer.

Circulature Coolant System makes it easy to manage processing chips and coolants.

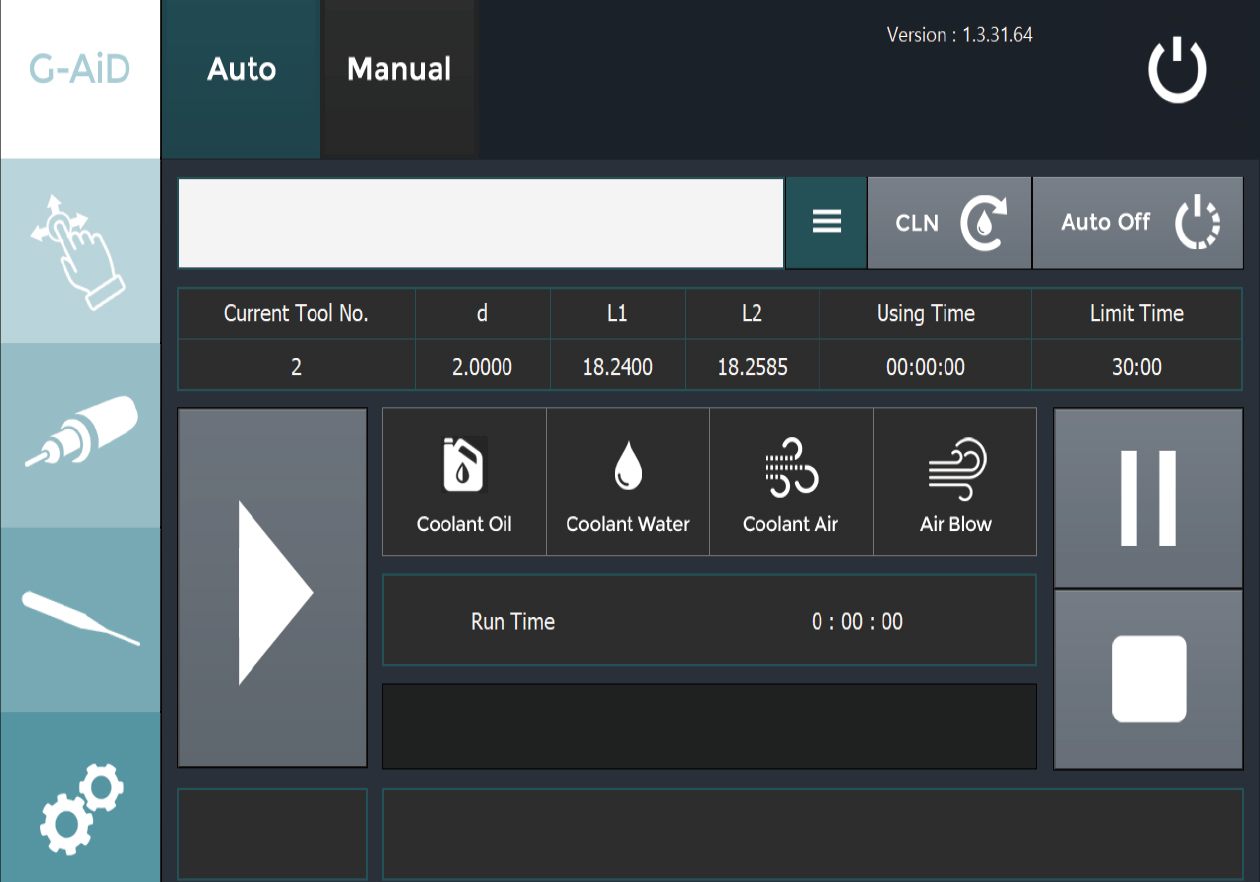

The SW developed by the user and the intuitive UI based on the touchpad, so that non -experts and students can easily operate.

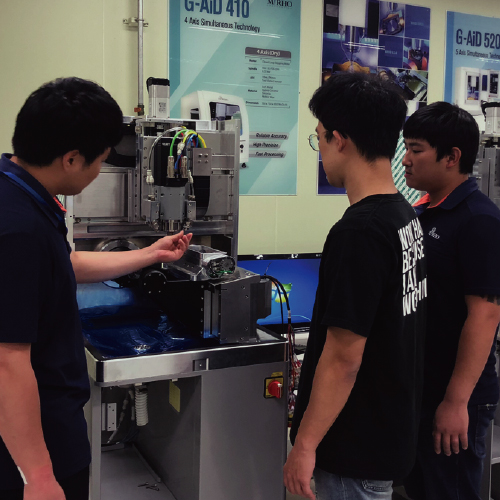

The space utilization is enhanced by the size that can be placed six units compared to one general MCT, and can be used at the same time in the lab or classroom.

It can be safely used as an automatic locking system to restrict the axis of axis and to prevent overload spindle.

When the processing is completed, the equipment is automatically off, so there is no need to keep the machine in front of the machine all night.

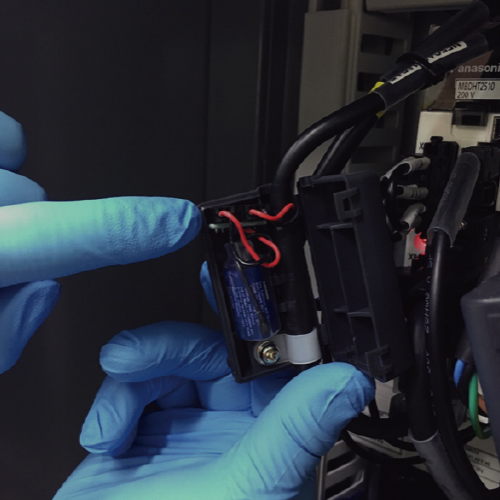

You can automatically measure the tool length with the attachment of the tool sensor in ATC to check the tool wear and the timing of replacing the tool accordingly.

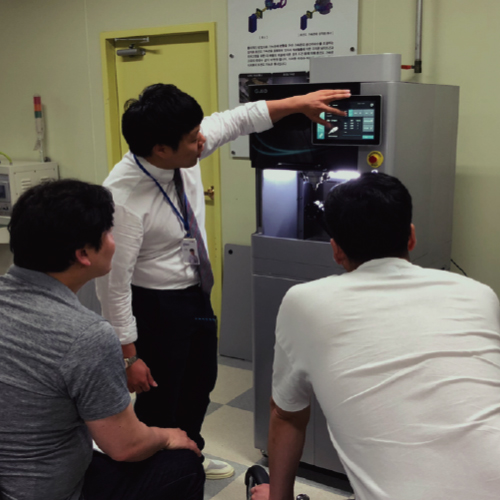

1. Provide basic equipment management training

2. Precision setting and maintenance training provided

It supports the zig technology coordination in line with the customer's processing language plan, and supports the best processing solution to make the customer process more efficiently.

In case of alarm and problems, remote support and visit A/S are supported to solve the problem quickly, and the main parts of the equipment are always managed by the head office to reduce the time required for the A/S.